Gantry machining centre and gantry milling machine, as an important member of large-scale CNC machine tools, each plays an indispensable role in the field of machining. Although the two names are similar, but in the structure, function, application and degree of automation there are significant differences. This article will be from a number of dimensions in-depth analysis of the differences between gantry machining centres and gantry milling machines, so that readers can make more informed decisions when choosing equipment.

I. Structural characteristics

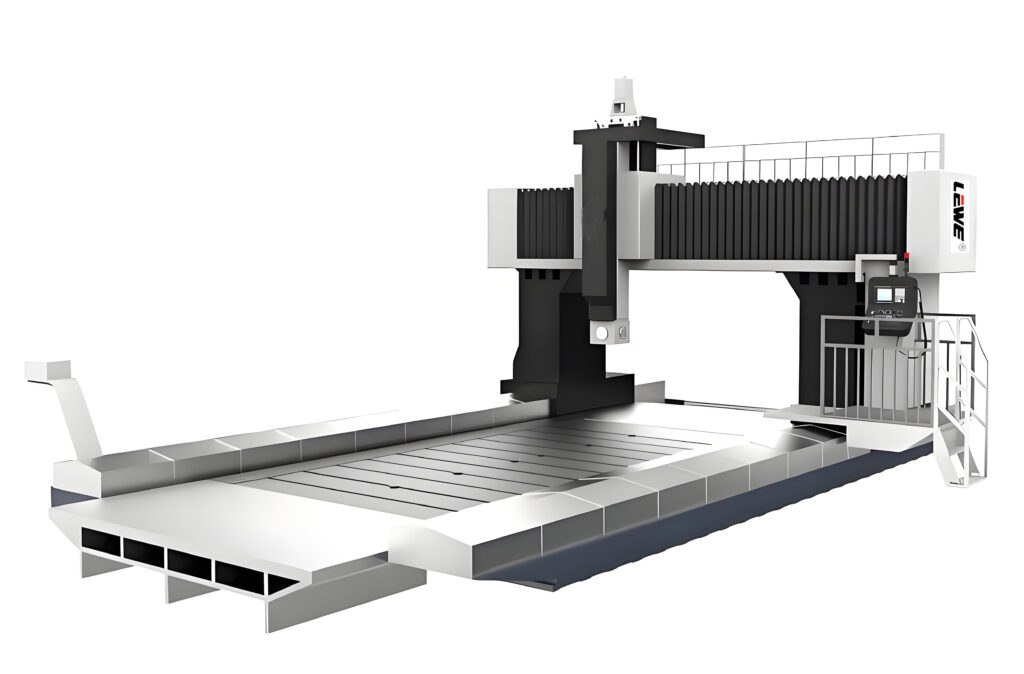

Gantry machining centres are known for their unique gantry rigid structure, consisting of double columns and top beams that form a sturdy frame, with an intermediate beam connecting the two columns, providing the machine with extreme stability and rigidity. This design enables gantry machining centres to withstand heavy loads and maintain high accuracy for long periods of time. The table is usually rectangular in shape and is capable of carrying large parts for complex machining requirements.

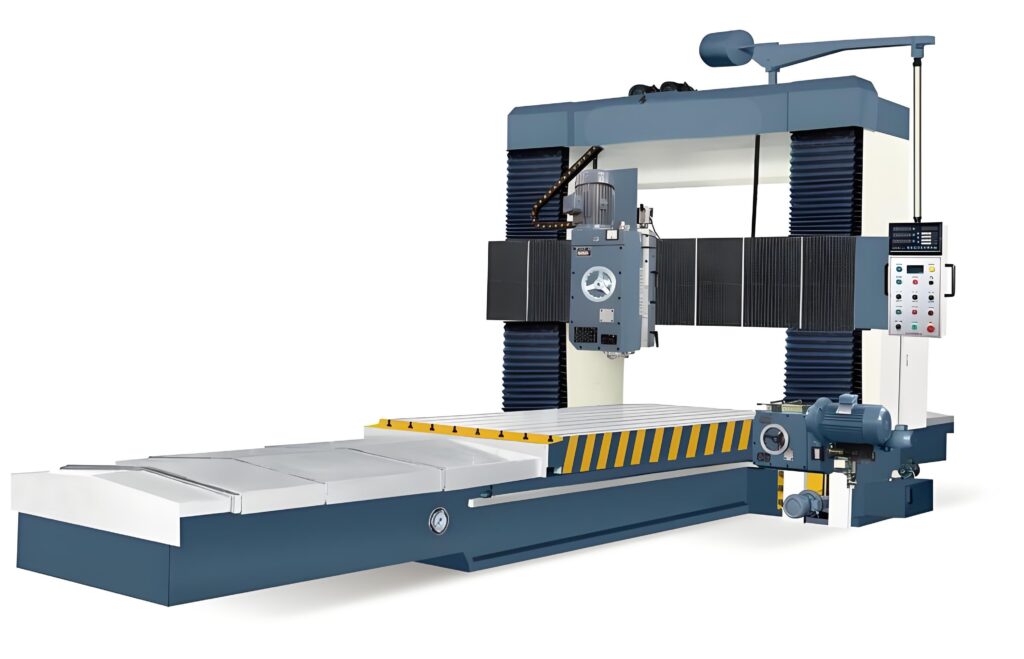

In contrast, gantry milling machines also use a gantry structure, but their main feature is that the milling spindle is suspended below the crossbeam, and the movement of the crossbeam enables a wide range of milling operations. Gantry milling machines can be classified into fixed gantry, mobile gantry and vertical/horizontal gantry milling machines according to the moving mode to meet different machining needs.

II. Functions and Applications

Gantry machining centres are known for their versatile machining capabilities with high accuracy and efficiency. It is usually equipped with an advanced numerical control (CNC) system that enables automated machining and supports a wide range of processes such as milling, drilling, tapping and slotting. Equipped with tool magazines and automatic tool changers, gantry machining centres are able to flexibly cope with a variety of complex machining tasks, and are widely used in aerospace, automotive, mould and die machining, and high-end mechanical parts.

Gantry milling machine is mainly focused on milling processing, its processing capacity is relatively single, but for large parts of the milling has significant advantages. Although it can also carry out some simple drilling and cutting operations, but mainly concentrated in the plane and three-dimensional milling. Gantry milling machine is widely used in heavy industry and manufacturing, such as shipbuilding, engineering machinery and large mould processing.

III. Automation and Intelligence

Gantry machining centre has significant advantages in automation and intelligence. Its advanced CNC system can not only achieve complex machining path planning, but also through the automatic tool change system to achieve rapid tool replacement, significantly improving processing efficiency and accuracy. In addition, some high-end gantry machining centres also support multi-axis linkage machining, which can handle more complex surface and angle machining tasks.

Although there are also CNC versions of gantry milling machines, the degree of automation and intelligence is lower compared to machining centres. Most gantry milling machines are still manually or semi-automatically controlled, requiring operators to rely more on manual labour to complete machining tasks. This limits the further improvement of its machining efficiency and precision to a certain extent.

IV. Accuracy and Efficiency

Gantry machining centres are renowned for their high accuracy and efficiency. With advanced CNC and automatic tool changer systems, gantry machining centres are able to ensure accuracy and consistency in the machining process, while significantly increasing productivity. In addition, their large stroke and load-bearing capabilities allow gantry machining centres to handle larger sizes and heavier workpieces.

Gantry milling machines also excel in accuracy and efficiency, but their machining capabilities are relatively homogeneous and limited by manual or semi-automatic controls. However, for milling large parts, the gantry milling machine is still an economical and practical choice.

V. Cost and applicability

From the cost point of view, gantry machining centres are relatively expensive due to their complex structure and high technical content. This makes it more suitable for production environments that require high output value and high precision. Gantry milling machines, on the other hand, are more favoured by small and medium-sized enterprises or occasions that do not require particularly high machining accuracy due to their lower cost.

In terms of applicability, gantry machining centres are suitable for the machining of complex parts due to their versatility and high precision; while gantry milling machines are more suitable for milling and dressing work of large parts. Therefore, the choice of equipment needs to be based on specific processing needs and budget for comprehensive consideration.