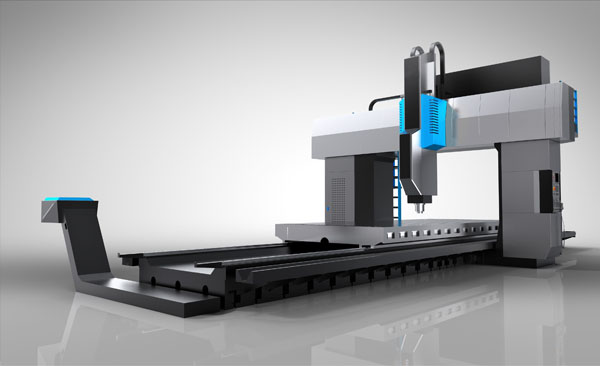

What is the CNC Gantry Machining Center

A gantry machining center (or gantry milling machine, gantry mill) is a distinctive machine tool with a double-column structure. The gantry refers to the CNC milling machine that hangs above the work table to perform machining operations. It is the rapid movement of the gantry that makes this machine particularly efficient.it is used in aerospace, rail transit, new energy vehicle battery trays, door and window curtain walls, TV frames, aluminum smart homes, tents, bathrooms, Aluminum profile processing, industrial profile processing, and other fields are widely used.

Structure

The design of the portal mill is quite simple. It consists of the gantry mill (along with two support columns) and the work table. The worktable allows for the installation of work-holding systems such as chucks, vices, etc. The gantry router is where the machining spindle is located.

The gantry contains a power system (often a motor) to move and operate the spindle. The spindle can move freely along the gantry (Y-axis) and the gantry can move freely along the longitudinal axis (X-axis) of the work table. Therefore, a typical gantry mill has at least two machining axes.

Multi-Axis Capability

As you may know, a modern gantry machine has more than two axes. The more axes the machine has, the more complex cuts it can make on a workpiece. Unlike vertical or horizontal machining centers, which have more than one spindle to achieve multi-axis machining, a gantry machine has only one spindle, and the axes are provided solely by the router.

The third axis usually comes from the rotation of the spindle to the vertical axis. It allows the cutting tool to locate a point at a higher speed. The fourth axis is provided by the swivel head design. The spindle can swing up to 90 degrees to cut the sides of the workpiece. These two axes can also be achieved by a tilting rotary table. The fifth axis refers to the rotation axis when the spindle swivels.

Quick-change tooling

A modern gantry mill is powerful not only because of the freedom to machine at multiple angles but also because of the accessories that increase its efficiency. One of the most important accessories is the quick-change tooling system. The quick-change tooling system is professionally known as quick-change tooling. It refers to an automated modular system that allows tools to be changed quickly on a machine. It is advantageous because the machine can switch between operations with minimal time cost. Reduced machine downtime means increased productivity.

Applications

The operations that can be performed on a gantry machining center include milling, facing, boring, drilling, tapping, reaming, etc. In this respect, a gantry machine is no different from a standard milling machine. However, because of the bed size, gantry machines can machine larger, longer, and heavier workpieces. They often machine workpieces that are meters in length and width and tons in weight. This feature is especially beneficial to the aerospace, automotive, and military/defense industries, which require the production of large dies/molds.