When it comes to manufacturing, machining technology is an indispensable link. The machining process is the process of converting raw materials into the required shape, size, and surface quality, covering a variety of precision machining methods to meet the needs of different parts. The following will introduce 8 common machining processes in detail.

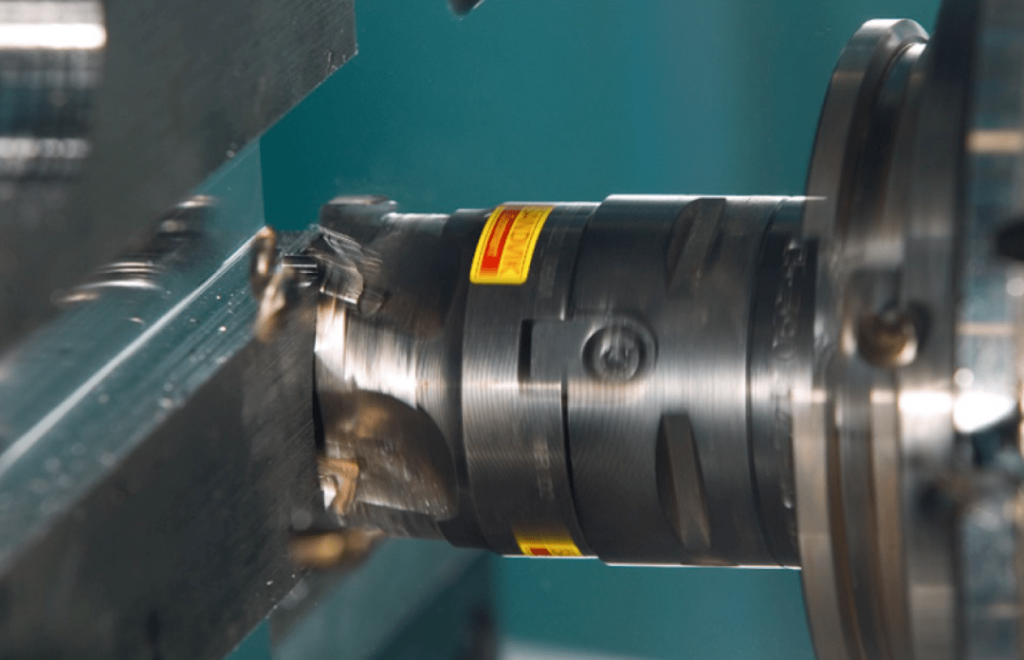

1. Turning

Turning is the process of holding a workpiece on a rotating workholding device and then using a tool to gradually remove material from the workpiece to obtain the desired shape and size. This processing method is suitable for manufacturing cylindrical parts such as shafts and sleeves. The turning method and tool selection affect the shape and surface roughness of the final product.

Turning can be divided into different types, including external turning, internal turning, plane turning, thread turning, etc.

External cylindrical turning is usually used to process shapes such as shafts, cylinders and cones; in internal cylindrical turning, the tool enters the inner hole of the workpiece and processes the diameter and surface of the inner hole to the required size and accuracy; turning planes are usually used For making flat surfaces, such as the base or end face of parts; thread turning is to gradually cut out thread shapes, including internal threads and external threads, by moving the cutting edge of the tool relative to the surface of the workpiece.

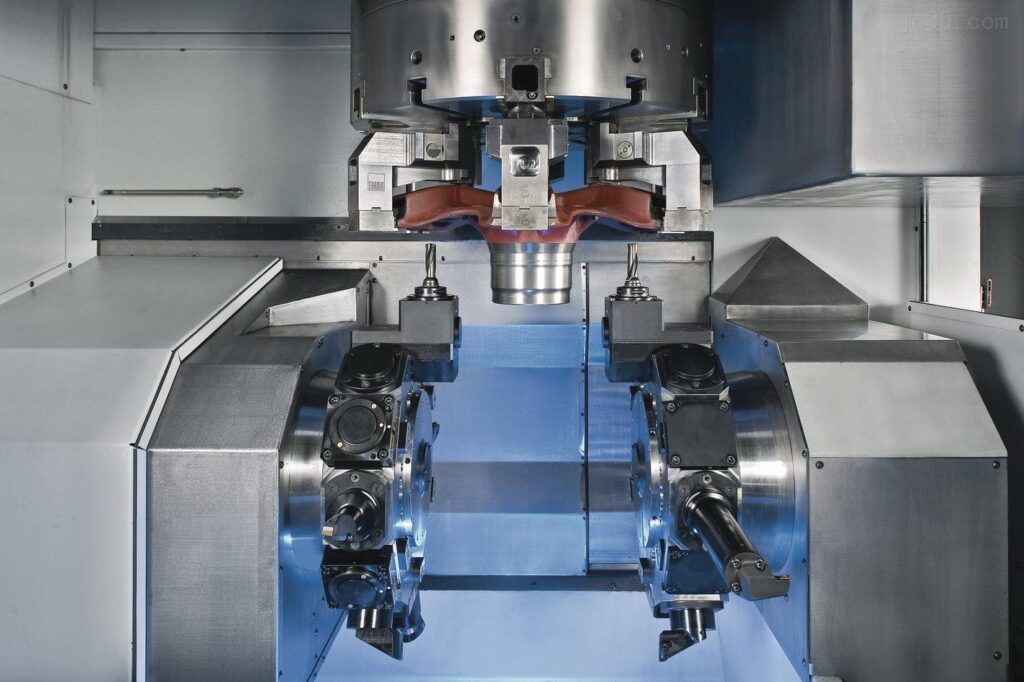

2. Milling

Milling uses a rotating tool to cut material on the surface of the workpiece. By controlling the movement of the tool, parts with complex shapes such as planes, concave, and convex surfaces, and gears can be manufactured. Milling includes plane milling, vertical milling, end milling, gear milling, contour milling, etc. Each method is suitable for different processing needs.

In-plane milling, the cutting edge of the tool cuts on the surface of the workpiece to obtain a flat surface; end milling is often used to machine grooves and holes along the height direction of the workpiece; end milling cuts on the side of the workpiece and is often used for machining Contours, grooves, and edges, etc.; gear milling usually uses special tools with cutting edges to cut out the tooth shape of the gear; contour milling is used to process complex curves or contour shapes, and the path of the tool is precisely controlled according to the contour

3. Drilling

Drilling is the use of a rotating drill bit to cut material on a workpiece to form a hole of the required diameter and depth. It is widely used in manufacturing, construction, and maintenance fields. Drilling is often divided into different types such as conventional drilling, center drilling, deep hole drilling, and multi-axis drilling.

Conventional drilling uses a drill bit with a spiral cutting edge and is generally used for smaller holes and general drilling needs; center drilling first creates a small hole on the surface of the workpiece and then drills it using a larger drill bit, ensuring that the location of large holes is accurate; deep hole drilling is used to process deeper holes, which requires special drill bits and cooling technology to ensure the accuracy and quality of processing; multi-axis drilling uses multiple drill bits at different angles Simultaneous drilling is suitable for processing multiple holes at the same time.

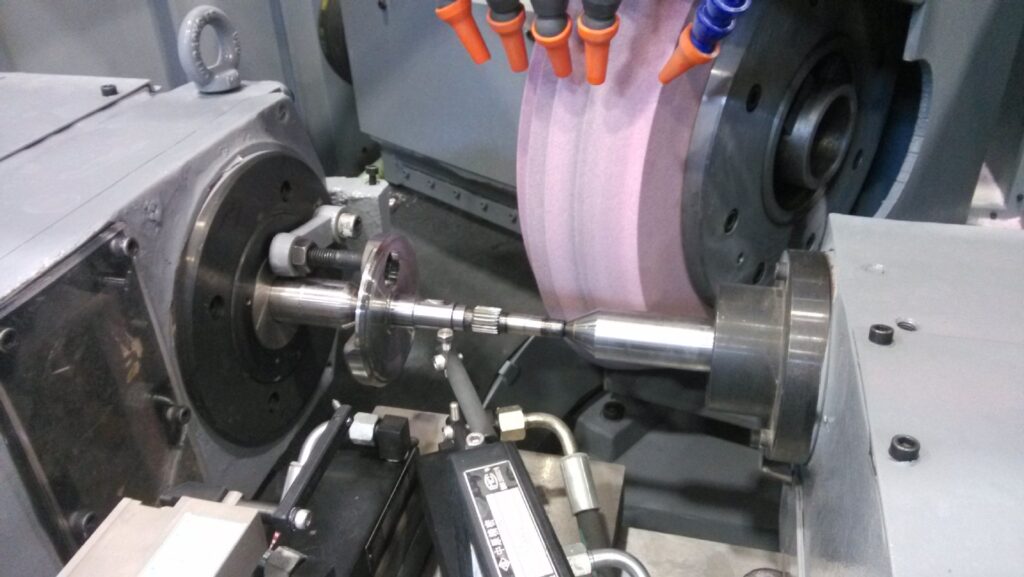

4 Grinding

Grinding is the gradual cutting or grinding of material on the surface of a workpiece by using abrasive tools to obtain the desired shape, size and surface quality. Grinding is usually used to process parts with high precision and high surface quality requirements, such as molds, precision mechanical parts, tools, etc.

Grinding is divided into surface grinding, cylindrical grinding, internal cylindrical grinding and contour grinding. Surface grinding is used to process flat workpiece surfaces to obtain flat surfaces and precise dimensions; cylindrical grinding is used to process the cylindrical surface of cylindrical workpieces, such as shafts, pins, etc.; internal cylindrical grinding is used to process holes. Internal surfaces, such as inner holes, shaft holes, etc.; contour grinding is used to process complex contour shapes, such as the cutting edges of molds and tools.

5.Boring

Boring is generally used to machine circular holes inside workpieces, using a rotating tool to cut into the existing hole to achieve precise dimensions and flatness. Unlike drilling, which creates holes by cutting material on the surface of a workpiece, boring cuts holes by inserting a tool inside the workpiece.

Boring is divided into manual boring and CNC boring. Manual boring is suitable for small batch production and simple machining tasks; CNC boring determines the cutting path, feed rate, and rotation speed through programming to achieve automated high-precision machining.

6.Planing

Planing involves cutting material over the surface of a workpiece using a planer blade to obtain the desired flat surface, precise dimensions, and surface quality. Planing is usually used to machine flat surfaces of larger workpieces, such as bases, machine beds, etc. It provides a flat surface for the workpiece, making it suitable for use with other workpieces.

Planing is usually divided into two stages: roughing and finishing. During the roughing stage, the planer cuts deeper to remove material quickly. During the finishing stage, the depth of cut is reduced to achieve higher surface quality and dimensional accuracy. Planing is divided into two types: manual planing and automatic planing. Manual planning is used for small batch production and simple machining tasks; automatic planing uses automated machine tools to control the movement of the planer to achieve a more stable and efficient machining process.

7.Broaching

Slotting uses a slotting tool to gradually deepen the cut and create complex internal contours. It is often used to machine complex shapes such as contours, grooves, and holes in workpieces. Plunging can usually achieve higher machining accuracy and surface quality, and is suitable for parts that require high precision and good surface quality. Generally divided into plane slotting, contour slotting, groove slotting, hole slotting and other types.

Surface slotting is used to process flat workpiece surfaces to obtain flat surfaces and precise dimensions; contour slotting is used to process complex contour shapes, such as molds, parts, etc.; groove slotting is used to process grooves and grooves, the cutting edge enters the workpiece and cuts along the surface of the workpiece; hole inserting is used to process the inner contour of the hole, and the cutting edge enters the hole and cuts the inner surface of the hole.

8.EDM

Electric discharge machining uses arc discharge to cut and process conductive materials to obtain high-precision, complex-shaped parts such as molds and tools. It is commonly used in manufacturing molds, plastic injection molds, aerospace engine parts, medical equipment and other fields. EDM is usually used to process hard, brittle or high-hardness materials that are difficult to cut with traditional machining methods, such as tool steel, carbide, titanium alloys, etc.

- Non-contact cutting: Different from traditional mechanical cutting, EDM is a non-contact processing method. There is no direct physical contact between the tool and the workpiece, but an arc discharge is used to strip the material.

- High precision: EDM can achieve high-precision processing, usually reaching sub-micron dimensional accuracy. This makes it suitable for manufacturing molds, models and other precision parts that require high precision.

- Complex shapes: Since EDM is a non-contact processing method, it can be used to process very complex shapes, including internal contours, small holes, grooves, etc.

- Suitable for materials with high hardness: EDM is suitable for materials with higher hardness because it does not rely on the hardness of the tool in traditional cutting methods.

The above are 8 common machining processes. Each machining process has its specific application areas and advantages. Selecting the appropriate process depends on the material, shape, size and surface requirements of the part.